|

Technical Specifications |

|

Disassembly of both brands was

relatively straightforward. The tools necessary were: Crescent Wrench,

Shock End Cap Spanner, Small Flathead Screw Driver, Large Internal Snap

Ring Pliers, Small Allen Wrench, and a Rubber Mallet. |

|

FOX: The bearing assembly body is made

of 6061 aluminum. The Slit in the side of the bearing assembly made purging the air

out of the shock easy. The seals are made of Buna. The internal bearing is

made of bronze with a teflon coating. Retails for $35

complete w/seals. (Part # 812-07-002-a) or $20 w/o seals (Part# 203-00-003-b) |

KING: The bearing assembly is made of 6061

aluminum. The aluminum washer on top of the main seal of Kings

Bearing Assembly retains the main seal. King's Shock seals are made of

Buna. The internal bearing or guide bushing is made of bronze with a teflon coating. |

|

FOX: The Spring Divider from Fox is made from

injection molded glass impregnated nylon and Retails for $15. (Part #

234-00-035-a) |

KING: The Spring Divider or Floater is made

out of either urethane, injection molded glass impregnated nylon or billet aluminum,

depending on what you order from KING. The polyurethane divider retails

for $15 The nylon divider retails for $15 and the aluminum floater retails for $50

The spring divider pictured is nylon and significantly thicker. |

|

FOX: The dust cap is made of

6061 aluminum

anodized blue. The Scraper seal is made of a compound called "Buna". |

KING: The dust cap is made of 6061 aluminum,

and the scraper seal is made of a compound called "Buna".. |

|

FOX: The Snap Ring from Fox is one heavy duty

unit. These are made of steel and gold zinc plated. Retail is $2 (Part #038-00-008-a) |

KING: These are standard snap rings made of

spring steel. |

|

FOX: While this type of lower spring seat

involves more parts, it allows maximum coil spring length to be utilized.

The spring seat is made of 6061 aluminum and anodized blue. The

retaining clips are made of steel. The spring seat retails for $25

(Part# 234-00-032-a). The retaining clips retail for

$9ea (Part# 234-00-031-a) The o-ring retails for $1

(Part# 029-00-031-a) |

KING: These lower

spring seats are of solid

design. They install by slipping over the shaft and lower eyelet, and are

made of 6061 aluminum. One drawback of this design is reduced usable shock

travel. Shown is the 2" raised lower spring seat. Retails for $30 |

|

FOX: The IFP (Internal Floating Piston) from

Fox is substantially lighter than King's. This reduces the momentum of the

oil as it plunges in and out of the reservoir. The wear band is made of

teflon. The IFP retails for $20 w/o-ring (Part# 805-00-001-a)

or $18 w/o o-ring (Part# 223-00-005-b) The wear band

retails for $3.50 (Part# 002-00-005-b) |

KING: The wear band is made of hard teflon

and the Floating piston is made of 6061 aluminum. The solid aluminum

floating piston is heavy, but additional machining translates to

additional price. |

|

FOX: The working piston is made from hard

anodized 6061 aluminum

and the wear band is made of a hard plastic called "PEET" The piston's overall diameter was

measured at 2.268". The wear band's height was measured at .37" |

KING: The working piston is made from 6061

aluminum and the wear band is made from a teflon bronze composite. The

pistons overall diameter was measured at 2.379" the wear bands height

was measured at .5" |

|

FOX: The compression side of the working

piston has four ports covered by seven shims varying in thickness based on

the shock's valving. The ports are ovalized as well as conically bored.

The minimum flow area we measured is .844 in².

The rebound side of the working piston has

four circular ports bored conically. The shim stack consists of six shims

of varying thickness based on valving chosen. Each port was measured at

.31" in diameter yielding a total flow area of .302 in². |

KING: The compression side of the working

piston has six ports covered by six shims that vary in thickness based on

the shocks valve rate. The diameter of each port is .375" making the

minimum flow area .663 in² the ports

are bored straight. The rebound side of the piston has three ports at

.329" diameter each. There are six shims that vary in thickness on the

rebound side based on valve stacks used. Total area for flow on the

rebound ports is .255 in² The ports are bored

straight. |

|

FOX: The heim spacers from Fox are made of

4130 chromoly steel. |

KING: The heim spacers from King are made of

4130 chromoly steel. |

|

FOX: The shaft spacers are machined from 6061

aluminum. |

KING: The shaft spacer is made of 6061

aluminum tube. |

|

FOX: The reservoir end cap is made of

6061 aluminum and anodized blue. Fox utilizes a special brass schrader valve with

an o-ring seal built in. Shock pressures can vary widely depending upon

setup. |

KING: The reservoir end cap is made from 6061

aluminum and anodized blue. The schrader valve uses a standard stainless

steel 1/8" NPT thread pitch and seals with teflon tape. Shock pressures

can vary widely depending upon setup. |

|

FOX: These valve shims are made of Sandvik 20

steel and then tumbled to remove any sharp edges. The shims can vary in

diameter from 2" - .8" and in thickness from .006" - .015". Shim stacks

are different from compression to rebound in number and size. Shims sell

for $1 ea or slightly less in a stack. They are also available in a kit

for $200. |

KING: The engineering Dept. at King would not disclose the

material their shims are made of, but based on our observations we would

guess spring steel. Shim stacks utilize six different diameters: 1.75",

1.6", 1.45", 1.3", 1.15", and 1.01". Thickness options are: .008", .010",

.012", .015", and .020". Shims sell for $2.75 ea or

$16 per stack. |

|

FOX: These stop washers keep the shock from

overextending. The washer is made from stamped steel. |

KING: These stop washers keep the shock from

overextending. The washer is made of stamped steel. |

|

FOX: These washers are designed to be

adjustable for the different height and type of shim stacks utilized. Fox

uses a lock nut to retain the working piston and shaft assembly

components. These are torqued to 35 ft/lbs. |

KING: The top nut on the shaft is a heavy

duty jam nut. Red Locktite is used to keep the nut from backing off.

Different height washers are available for purchase from King. Maximum

torque is significantly higher. |

|

FOX: The reservoir from Fox has the advantage

of more oil capacity and greater surface area for cooling. The ribs also

provide extra strength. Fox reservoirs are made from low carbon DOM steel

tubing. Length is 14". |

KING: The reservoir

body is made from 6063 drawn aluminum tube. While aluminum radiates heat

better we have found that the tube and the floating piston have .005"

looser tolerances, thermal expansion slightly exacerbates this. This is the main reason

we find small amounts of oil bypassing the floating piston and moving into

the nitrogen chamber. Length is 10.75". |

|

FOX: The eyelets from Fox are made of 6061

aluminum and always come with a rubber bump stop. Fox also utilizes FK Rod

Ends for their spherical bearings. |

KING: The eyelets are made from 6061 aluminum

with rubber bumpers available upon request. King would not disclose the

bearing manufacturer used. |

|

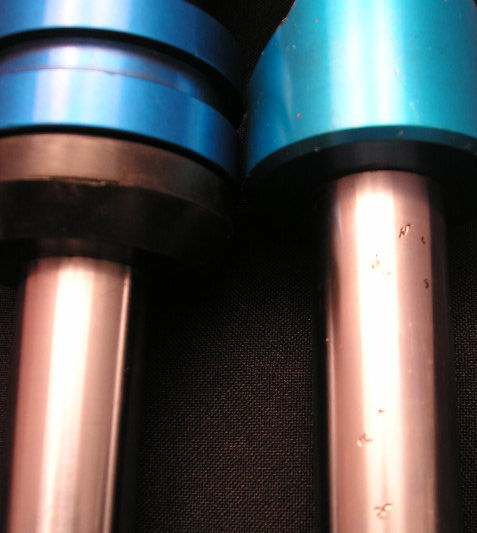

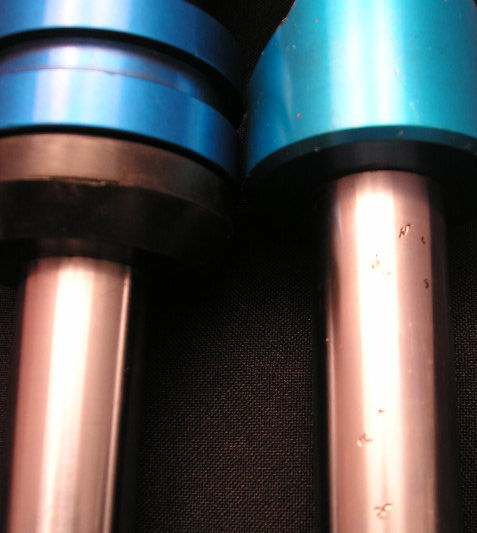

FOX: 17-4 Stainless steel shafts are utilized

on all Fox Shocks except for the 1.25" and 1.625" shaft air shocks. The

shafts on the 2.5 shock pictured is .875" in diameter. |

KING: The material

used would not be disclosed but we believe the shafts to be made of steel and hard chrome plated. A nice advantage of King shocks is

the chamfered edge where the seal assembly slips over. This makes for easy

reassembly without galling the wiper seal. |

|

FOX: A close up of the spring seat retaining

clip groove and rubber bumper. |

KING: An unfortunate effect of damaged

chromed steel shafts is rust pitting. If not properly lubricated and

protected the rust will continue to corrode the shaft and possibly damage

the seals and internal bearing. |

|

FOX: The reservoir lines are made from

Aeroquip High Pressure Hose and Steel reusable fittings. The hose is -10

and pressure rated to 1750 psi with 6 layers. All Fox shocks utilize

o-ring sealed steel JIC fittings. One drawback of this heavy duty hose is

it is less flexible. |

KING: The reservoir lines are made from

Aeroquip Racing Hose and crimped steel fittings. The hose is -10 and

pressure rated to 250 psi with 3 layers. King Shocks use pipe thread with

teflon tape to seal their fittings. One drawback of the low pressure hose

is the relatively small amount of compression ratio adjustment available. |

|

FOX: The shock body is made from low carbon

DOM steel tubing then honed and threaded. Fox top caps are smaller in

diameter than the body allowing spring hardware to be removed from the top

of the shock. This makes converting to triple rate easier. We

measured the tubing at 2.557" x .120". |

KING: The shock body is made from low carbon

DOM steel tubing then honed and threaded. The top cap must be removed to

install or remove coil hardware. This makes triple rate hardware more

difficult to install. We measured the tubing at 2.62" x .127". |

|

FOX: Seal kits for this shock retail for $15. |

KING: Seal kits for this shock retail for $20 |